OBS Quality Feeds: Homegrown Company Flourishes in Horse Country

by

Cynthia McFarland

For decades, the only feed mill in town was Seminole Feeds, which opened its first store in 1934 and began operating its mill in 1968.

Just over a dozen years later, a local co-op owned business expanded to increase the hometown feed options in Marion County.

Ocala Breeders’ Sales Company has established a well-deserved reputation as the 2-year-old sales venue in the U.S. Since its first 2-year-olds-in-training sale in January 1975, OBS has risen to prominence at the international level, even surpassing the hopes of its founders.

Photos Courtesy of OBS Quality Feeds

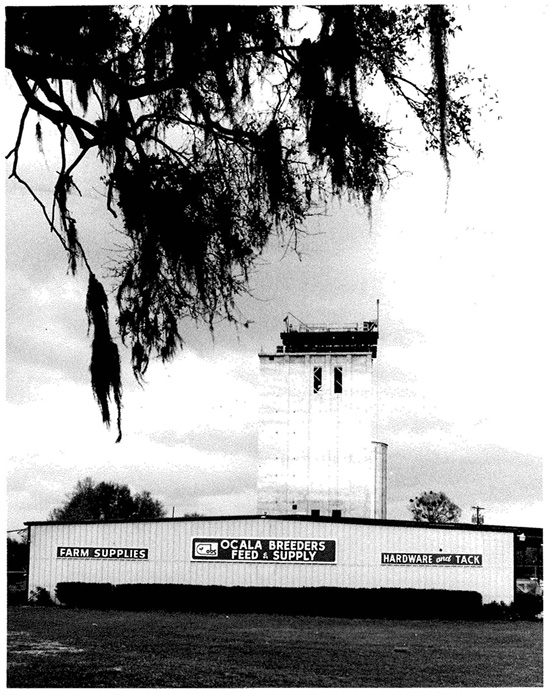

Most, if not all, of the original shareholders of Ocala Breeders’ Sales Company were horsemen themselves. Having a feed division made sense as a logical extension of the company. For a short time, the business bought feed to sell but in 1983, OBS built its own horse feed production plant on 27th Avenue in Ocala.

Dean Wright was general manager when the company got rolling. Ty Springer came on board in 2014. There have been only two general managers at Ocala Breeders’ Feed & Supply all these years.

Ocala Breeders’ Feed & Supply has three locations in Ocala. The Highway 27 and Airport Road locations are fully stocked retail stores, which also sell feed and hay. The mill location on 27th Avenue, which is also the corporate office, has feed sales only. OBS Quality Feeds are also sold at several local dealers, including Rural King, Williston Hay Company, Wagon Wheel in Brooksville, and Larsen Farms in Oxford.

Busy Mill

There is not a large warehouse to stockpile feed, so it is sold right after production. Every bag is stamped with the date that feed was produced. In keeping with the company’s emphasis on freshness, most feed is sold within a 30-mile radius of the mill.

The bagging area of the mill is brand new as of late August 2024.

Photos Courtesy of OBS Quality Feeds

“A robot takes bags off the conveyor belt and puts them on a pallet. This is a big improvement from when bags used to be stacked by four men. We have used a robot for about 15 years and recently upgraded it,” says general manager Ty Springer.

“We receive whole oats and corn by rail in large bulk amounts,” he says, noting that the train tracks are right at the back door of the mill location on 27th Avenue.

“We buy the best there is and only from certain companies that have the same integrity we do. The oats we buy are the same grade as what you’d get in human cereal. Our oats come out of Canada; our corn is grown in Indiana,” says Springer.

“We buy the best there is and only from certain companies that have the same integrity we do. The oats we buy are the same grade as what you’d get in human cereal. Our oats come out of Canada; our corn is grown in Indiana.”

Testing ensures that only the highest quality ingredients are used.

“We have mycotoxin testing and quality graded testing on every load we buy,” notes Springer. “We also have in-house mycotoxin testing and pull samples and test them.”

Mycotoxins are toxic substances produced by fungi that can contaminate plants and grain crops, including oats and corn.

Feed Production

Crackers, steamers, grinders and crimpers are among the mill’s machinery. At the heart of the mill is a mixer, (think of it as a giant mixing bowl), which handles 4,000 pounds at a time. That’s the equivalent of 80 bags of feed.

Since horses require different nutrients at different stages of life, the nutritional analysis of feed is critical.

“Our partnership with Kentucky Equine Research gives us direct access to cutting-edge science, which enables our team to provide the best service and research-backed recommendations to our customers,” says Springer. “We know our product line now reflects the latest research on optimal feeding practices for modern race, breeding, and sport horses.”

When soybean oil is part of the ingredients, this is added to the mixer, as is molasses.

“The majority of our feed is made with molasses. Even the pelleted feeds have a light application of molasses for palatability,” says Springer. “Thoroughbred buyers like their feed to have more molasses than the sport horse people, so we have OBS Sport Horse, which is a high fat, low starch feed which has no corn or oats and is light on molasses.”

Rigid Standards

“When you’re feeding million-dollar racehorses, quality is of the essence,” says Springer, noting that Triple Crown winner American Pharoah was fed OBS feed when he was broken and trained at McKathan Brothers Training Center.

Even if horses aren’t destined to become champions, owners want to know that their feed is safe and contains the best ingredients.

“The state of Florida requires us to submit so many samples of finished product based on the tons of feed produced every quarter. They test for protein, fat and fiber to analyze that the samples match the tags for each formula. We’re held to strict governing standards and are fined if it doesn’t match,” notes Springer.

Photos Courtesy of OBS Quality Feeds

“The state of Florida requires us to submit so many samples of finished product based on the tons of feed produced every quarter. They test for protein, fat and fiber to analyze that the samples match the tags for each formula. We’re held to strict governing standards and are fined if it doesn’t match.”

The mill is also FDA inspected.

“The FDA inspects the facilities on a regular basis, but without advance warning. They look for cross contamination of any kind. They also look at the protocols and procedures. Those protocols have to be written down and our employees have to be trained in it,” says Springer, adding that their motto is “Food Safe, Feed Safe.”

Photos Courtesy of OBS Quality Feeds

This means consumers don’t have to worry about any potentially dangerous medications accidentally finding their way into horse feed, which can have fatal results.

Unfortunately, that’s exactly what happened this summer when a rodeo stock contractor in Oklahoma received a bulk feed shipment that contained monensin. The drug is routinely used in cattle feed to improve feed efficiency but should never be fed to horses because even a small amount is toxic. Tragically, the ranch lost 70 to 80 horses.

Such accidents can happen in feed mills that produce multi-species feeds if there is a failed cleanout procedure or sensor malfunction. OBS Quality Feeds users never have to worry about this happening as the mill is totally drug free and only produces equine feed.

Trusted Source

As of mid-October, Eddie Woods ranked #4 among Leading Consignors for 2024 North American Sales having sold 49 head for $10,060,500 in 2024.

“We’ve been feeding OBS feeds since 1993,” says Woods, noting that his 2-year-old sale horses and older layup horses are all fed OBS Performance Blend, which is the choice of many 2-year-old consignors and trainers. The 12 percent protein textured feed is formulated for the high energy demands of yearlings and horses in training.

An OBS shareholder, Woods also serves on the board of directors. He especially likes the fact that OBS Feeds is backed by extensive research and that all feeds are fortified and balanced with KER micronutrients.

Local delivery is an added convenience. “We put in our order by barn and get a truckload delivered a week,” says Woods.

Photos Courtesy of OBS Quality Feeds

All Classes of Horses

Founded in 1976 by Arthur Appleton, one of the pioneers of Florida’s Thoroughbred industry, Bridlewood Farm has a rich history of breeding, raising and training stakes winners. Following Appleton’s death, the operation was purchased by John and Leslie Malone in 2013.

“We’ve been OBS shareholders since the inception of the company and have fed OBS feeds for many years,” says George Isaacs, Bridlewood’s long-time general manager.

In his many years of managing Bridlewood, Isaacs says he’s conducted his own in-house trials and tried other feeds, but always came back to the OBS brand. A big reason for that is knowing all OBS formulas are backed by extensive research.

“They hired Dr. Joe Pagan (of Kentucky Equine Research), one of the foremost equine nutritionists in the world, to reformulate their feeds,” says Isaacs. “Dr. Pagan does more boots on the ground research than anyone, so I have 1000 percent confidence in him and am glad he’s part of the OBS team. He has ‘looked under the hood’ so we can use OBS feeds with confidence and know we can raise a good horse on it.”

If you would like to read other equestrian related posts please be sure to check out some of our previous features.

Pint-size Companions Deliver Full-Sized Fun

Photo Courtesy of Stacy Furgang, DMVPint-size...

Community Spotlight | Law Enforcement on Hooves

Law Enforcement on Hooves: Mounted Units at Home...

Seminole Feed | 90 Years of Serving Ocala

Seminole Feed : Hometown Feed Mill Celebrates 90...

Hurricane Season | Tips For Residential & Equestrian Properties

Hurricanes are a familiar sight to many...

Beyond Racing | Off-the-Track-Thoroughbreds Excel in New Careers

Beyond Racing: Off-the-Track-Thoroughbreds Excel...

2024 Belmont Stakes Horses with Ocala Connections

The final jewel of the Triple Crown series gets...